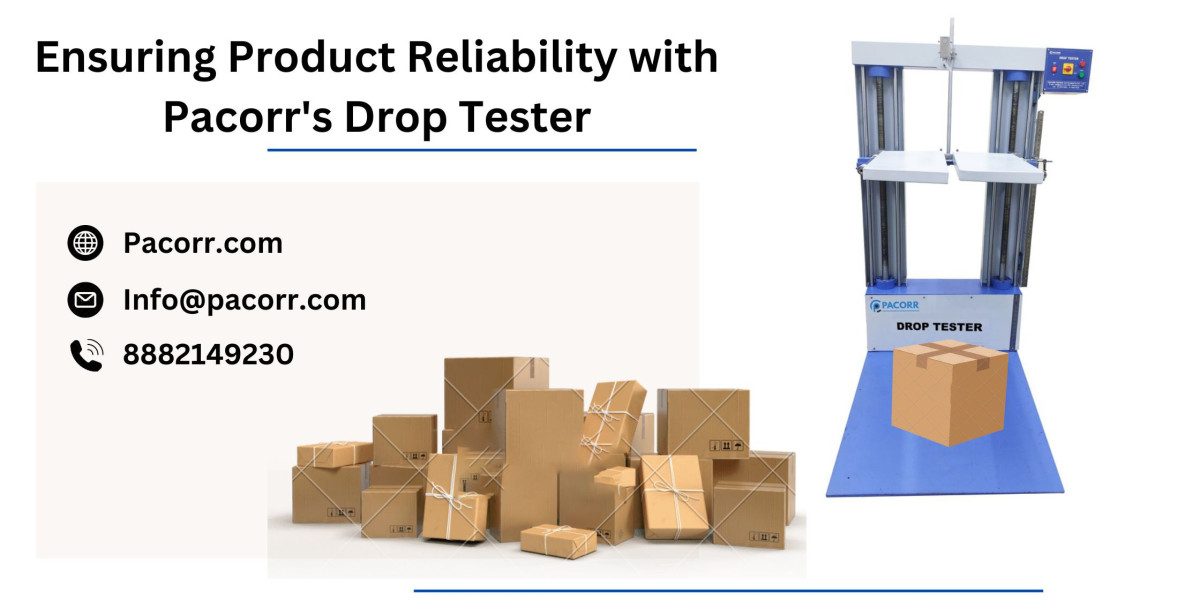

To help manufacturers ensure their packaging is up to the task, Pacorr Testing Instruments Pvt Ltd introduces the Drop Tester—a precise tool designed to simulate the real-world conditions of shipping and evaluate the effectiveness of packaging materials in protecting products.

What is a Drop Tester?

A Drop Tester is a specialized device that simulates the type of drops and impacts products experience during transit. By dropping packaged items from controlled heights and angles, this tool helps assess how well the packaging absorbs shock and protects the product inside. This valuable testing allows manufacturers to make necessary adjustments to their packaging designs to ensure maximum protection and durability during shipping.

Why is Drop Testing Important?

Shipping products exposes them to a variety of hazards. From accidental drops during loading to bumps along the way, without the right packaging, products are at risk of damage. Drop testing helps to simulate these challenges and test the strength of your packaging to ensure it can handle real-world shipping conditions, reducing the risk of damage.

Key reasons to incorporate drop testing into your packaging design include:

Prevents Product Damage: Ensures that packaging is strong enough to protect products during handling and shipping.

Cost Savings: Reduces the financial impact of returns, replacements, and repairs caused by packaging failure.

Optimizes Packaging Design: Provides insights into areas where packaging can be improved for better protection and durability.

Features of Pacorr’s Drop Tester

Pacorr’s Drop Tester comes with several advanced features that make it a valuable tool for testing packaging strength:

Adjustable Drop Heights: You can set different drop heights, simulating multiple shipping scenarios, and thoroughly testing your packaging’s resilience.

Compatibility with Various Packaging Materials: Whether testing cardboard, plastic, glass, or other materials, the Drop Tester accommodates various packaging types, making it ideal for different industries.

Accurate Testing Results: The Drop Tester provides consistent and repeatable results, helping you identify areas of improvement in your packaging design.

Simple Operation: Designed with user-friendliness in mind, the Drop Tester allows for easy operation with minimal training.

Durable Construction: Built with long-term use in mind, this tester is made from durable materials that can handle frequent testing, ensuring it lasts for years to come.

Applications of the Drop Tester

The Drop Tester is essential in industries where packaging protection plays a crucial role in product safety. Key applications include:

Electronics: For products like smartphones, tablets, and computers, packaging must be shock-resistant. Drop testing ensures that the packaging can protect fragile electronics during shipping.

Consumer Goods: Items such as cosmetics, toys, and home appliances need to be shielded from impact during transit. Drop testing ensures that the packaging provides adequate protection for these products.

Food and Beverage: In the food industry, packaging must remain intact to prevent contamination and preserve freshness. Drop testing ensures that food packaging can endure the shocks and drops during shipping.

Pharmaceuticals: Medicines and medical devices need to be carefully packaged to avoid damage that could compromise their quality or safety. Drop testing ensures that pharmaceutical packaging remains intact during transportation.

Industrial Products: For heavy-duty tools and machinery, packaging must be designed to withstand rough handling. Drop testing confirms that packaging provides adequate protection for these products.

Benefits of Using Pacorr’s Drop Tester

Prevents Product Damage: The Drop Tester helps prevent packaging failures, ensuring your products are protected from drops and impacts during shipping.

Enhances Packaging Design: Drop testing reveals weaknesses in your packaging, allowing you to make improvements and strengthen your packaging designs.

Cost-Effective: By preventing product damage and reducing returns, drop testing helps save money on replacements and repairs.

Improves Customer Satisfaction: When products arrive safely and undamaged, customer satisfaction increases, resulting in repeat business and positive reviews.

Meets Industry Standards: Drop testing ensures that your packaging meets the necessary industry standards, keeping your business compliant with regulations and safety requirements.

Why Choose Pacorr’s Drop Tester?

The Drop Tester Price from Pacorr is an essential tool for businesses looking to ensure that their packaging can withstand the stresses of transportation. With features like adjustable drop heights, the ability to test a variety of materials, and consistent results, it provides the insights needed to improve packaging durability. By incorporating drop testing into your packaging development process, you can reduce product damage, improve customer satisfaction, and save on costs.