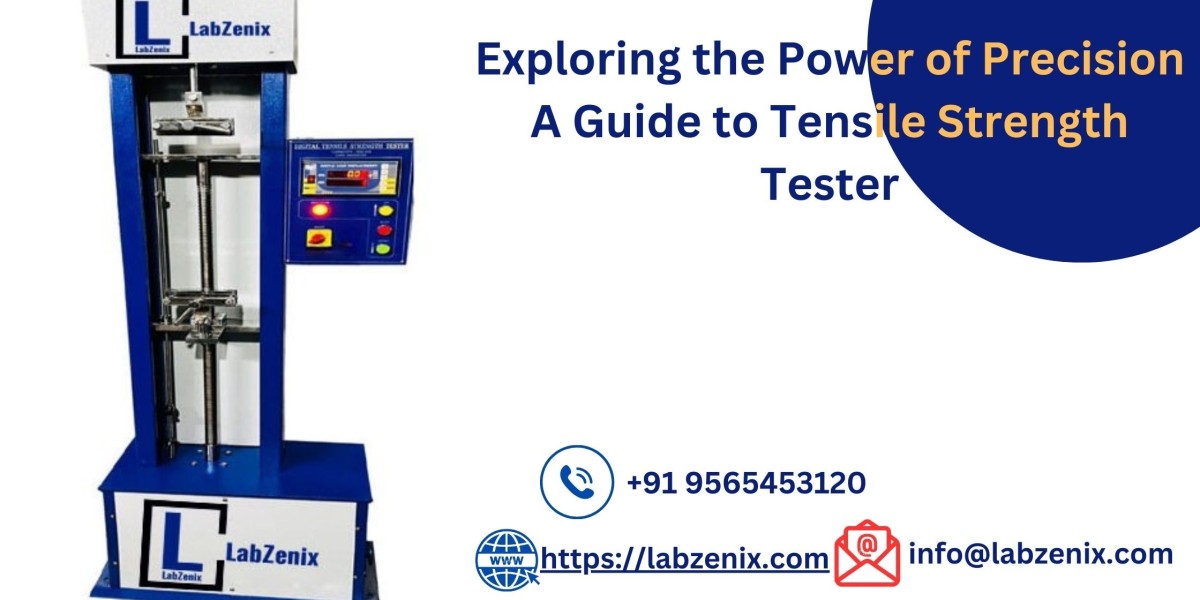

At Labzenix.com, we specialize in providing state-of-the-art tensile strength testing solutions tailored to various industry needs.

What Are Tensile Strength Testers?

Tensile strength tester are advanced instruments designed to measure the tensile properties of materials such as metals, polymers, textiles, and composites. By applying controlled tension, these testers reveal crucial characteristics like breaking points, elongation, and stress-strain behavior.

Why Is Tensile Strength Testing Important?

Tensile strength testing is a cornerstone of material validation. Here’s why it’s critical:

Improved Safety: Testing ensures materials meet safety standards, minimizing the risk of failures.

Quality Assurance: Regular testing ensures consistent and reliable material performance during production.

Material Innovation: Drives the development of new materials with enhanced properties.

Regulatory Compliance: Meets strict standards from ASTM, ISO, and other regulatory bodies.

Key Features of Modern Tensile Strength Testers

Modern tensile strength testers are designed with precision and adaptability. Key features include:

Precision Sensors: Deliver highly accurate measurements for reliable results.

Flexible Grips: Accommodate a variety of material shapes and sizes.

Smart Interfaces: Real-time data visualization and automated analysis capabilities.

Robust Construction: Durable designs for demanding testing environments.

Test Versatility: Perform a variety of tests, from basic tensile strength assessments to multi-parameter evaluations.

Applications of Tensile Strength Testers

Tensile strength testing are indispensable across industries, including:

Textiles: Evaluating fabric strength for durability and performance.

Metal Fabrication: Testing structural integrity for construction, aerospace, and automotive industries.

Plastic Manufacturing: Assessing flexibility and resistance for packaging and industrial uses.

Rubber and Elastomer Production: Measuring elasticity and endurance for automotive components and industrial tools.

Composites Engineering: Ensuring reliability in high-performance engineering materials.

How to Choose the Right Tensile Strength Tester

Selecting the best tensile strength tester requires consideration of several factors:

Material Compatibility: Ensure the tester supports the materials you need to test.

Industry Standards: Verify adherence to applicable testing standards.

Level of Automation: Decide between manual, semi-automated, or fully automated systems.

Load Capacity: Match the machine’s range to your application requirements.

Budget and Durability: Prioritize a machine that delivers long-term value within your budget.

Why Partner with Labzenix?

At Labzenix.com, we are dedicated to delivering quality tensile strength testing solutions with exceptional service. Here’s what makes us your ideal partner:

Cutting-Edge Technology: Our machines offer unparalleled accuracy and efficiency.

Tailored Solutions: We design systems to meet your unique needs and specifications.

Outstanding Support: Our expert team assists with everything from installation to maintenance and troubleshooting.

Conclusion

Tensile strength tester price are integral for assessing material performance and ensuring compliance with industry standards. With Labzenix.com’s innovative solutions, you can elevate your quality control and material research capabilities to the next level.

Discover the perfect tensile strength tester for your business at Labzenix.com and achieve unparalleled precision in your testing processes.